According to the data released by India’s Ministry of Housing and Urban Affairs in January 2020 (Swachhata Sandesh Newsletter), 1,47,613 metric tonnes of solid waste are generated per day.

Unfortunately, the majority of this waste is dumped into landfills and is one of the main causes of environmental pollution.

In India, the volume of waste generation has been increasing rapidly over the last few years, especially plastic waste. The growing urban population, modern lifestyle, and increasing consumerism is causing larger quantities of plastic waste that local municipal bodies are unable to manage effectively.

As per the data from India’s central pollution control board (CPCB), plastic waste accounts for 8% of the total solid waste generated in the country annually. Of the 26,000 tonnes of plastic waste produced in India every day, the majority of that is single-use plastic bottles, soft drink bottles, or other recyclable materials.

While efforts are underway to encourage the use of plastic waste for road construction or waste to energy etc, but still the problem is huge.

That’s where Eco Deco has come to fill the gap by creating innovative products from plastic waste. Delhi-based startup Eco Deco by converting plastic waste into daily lifestyle products like bookshelves, planters, home furniture, public utility items is playing a huge role in sustainable development.

The company sources plastic waste from households and local vendors and then recycles the plastic waste into panels and boards. These panels are given shape to create products.

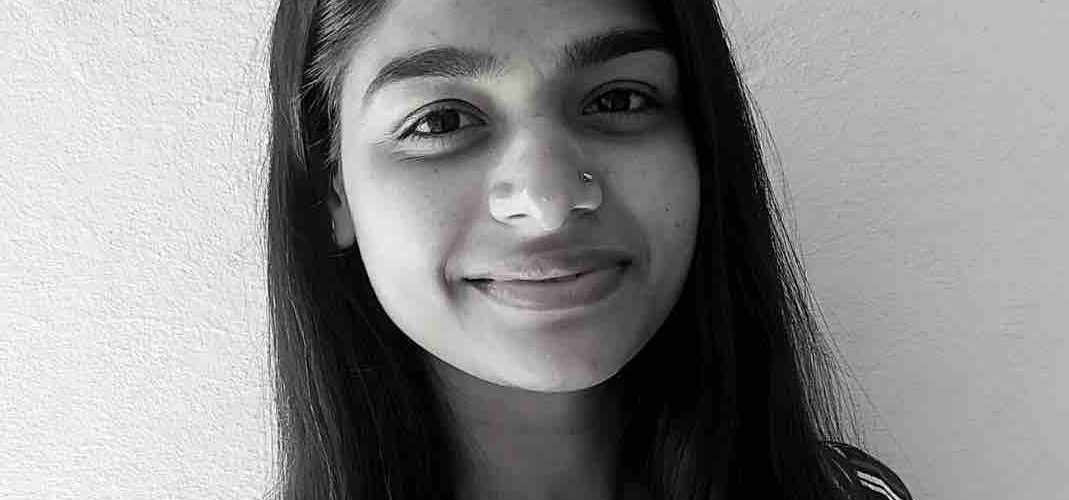

Here is an edited version/excerpts of our conversation with Sonal Shukla, on her journey, about Eco Deco, the idea behind the Eco Deco, and future plans. For the full discussion please watch the video.

Tell us about your journey prior to this venture?

I did my master’s from the National Institute of Technology (NIT), Kurukshetra in Electronic engineering and did an internship in the Very-large-scale integration (VLSI) domain.

How did the idea to start in Plastic Waste came about?

There is an interesting back story.

At NIT I met Vaibhav who was doing environmental engineering, together with a bunch of friends we went on a vacation to Himachal Pradesh in 2019. There we saw a huge amount of plastic waste & garbage scattered all over the place.

When we go to a tourist place, we want to enjoy nature and then to find garbage was extremely concerning for all of us. Vaibhav casually questioned the cause of so much garbage and enquired who is responsible for throwing so much waste.

Suddenly a kid who was passing by, quipped “People like you are responsible” and ran away.

This incident stuck with me.

Personally, I am always active in social causes, cleanliness drive, carrying litter bags – but never gave any serious thought to the plastic pollution problem. Vaibhav, because of his environmental engineering background helped me understand the plastic problem and possible solutions.

In May 2020, both of us zeroed in on a solution and make this a business opportunity, where Vaibhav will focus on production and I would work on the operations.

We registered the company in October 2020 and created a prototype of the product by December.

What is the product?

We take the waste plastic from the waste pickers (kabadiwalas) and households, do the necessary processing, and create panels, similar to plywood boards. The thickness of these boards is about 5 mm to 20 mm. These boards can be used to make furniture or home decor items like the bookshelf, planters, etc.

While there are sustainable products made with wood, bamboo, etc, but not much attention is given to create products out of the plastic waste which is already created. We need to create innovative products with this waste.

Our product also helps in reducing wood consumption, which will save trees.

What are the Product Categories?

We have two kinds of product categories –

- The first one is products made with recycled plastic that looks very appealing & creative. These products are for home purposes whereby people can use them and also flaunt them to their friends and relatives.

- The second one is for large-scale applications like benches and dustbins. These products are for the government and corporations.

What was the reason for getting into this sector?

We saw that there is a huge shift in consumer mindset where people are opting for more sustainable choices and products which create an impact on society as a whole.

People understand the plastic problem, but there are not many sustainable products made from recycled plastic in India.

Plastic is not going anywhere, we will keep producing plastic for various purposes, but we need to recycle this plastic and find a suitable use.

Plastic stays in the system for 400 years, if we can increase the usability of the plastic before it goes into the landfills, it will be great for the environment.

Our products also promote a circular economy, as products are not only made with plastic but are recyclable as well.

How does the process work?

We collect the plastic from our partners and households.

The next step is the segregation of plastic, as there are different kinds of plastic, we need to properly sort. If all kinds of plastic are mixed together, it will affect recyclability.

After segregation, we do the cleaning and shredding and post that it goes into the machine, which makes the board.

How much plastic is required to make a plastic board?

For a 4ft by 4ft board of 10 mm thickness, we would need about 12 kgs of plastic. If the thickness increases the quantity of plastic required also increases.

Can you tell us the different kinds of plastic?

Plastic is categorized from 1 to 7.

Type 1 of the most commonly used plastics, like the ones used for single-use plastic bottles.

Type 2 plastic is high-density polyethylene (HDPE) like shampoo bottles, milk jars, etc. We use mostly HDPE type of plastic for EcoDeco products.

Type 3 is Polyvinyl Chloride (PVC) like the plumbing pipes.

Type 4 is low-density polyethylene (LDPI) that includes single-use plastic bags, milk pouches. The interesting thing about milk pouches is that though it is recyclable, not many of us know that. People need to segregate this kind of plastic and keep it separate from the other kind of kitchen waste etc. We encourage our community to clean the milk packets, other types of food packets and give them to us.

Type 5 is Polypropylene (PP), which includes furniture, straws, etc.

Type 6 is Polystyrene (PS to styrofoam), which is again highly used because of food delivery companies. Type 6 include take-out containers, cups, and plates and the recyclability is low for this type.

Finally, there is Type 7, which includes all those items which are not part of other Types. We have created a prototype with this type of plastic as well.

What was the idea behind the name Eco Deco?

We are building products for the home decor segment. It was our planned decision to make products which on one side is waste but on the other side looks good and create an impact.

The name Eco Deco comes from 2 words – Eco which means eco-friendly and deco is for decoration.

We do customizations as well, where if a consumer wants to create a product with a particular design, we can do that. When the product is ready, we also send a “Thank You” note to consumers mentioning the amount of plastic they have helped in recycling and making an impact.

As of now, we are very flexible with the kind of products we make, like a bookshelf, wall shelves, planters, etc.

What are the challenges you have faced?

The biggest challenge was setting up the machinery, as we did not get the machine that we required.

The other challenge was finding the right partners. As our initial idea was to make the recycled plastic boards and then give them to designers to make products. However, due to many reasons, things did not work out and we decided to make the product ourselves.

What are the future plans and are you looking to raise money?

We want to work on the waste collection setup, where people can give their waste through a digital platform.

Additionally, we are doing research on what kind of other products can be made, like the ones which are currently made in plastic.

Every startup needs money and we are also looking for the same as that will help us in buying bigger machinery and create more impact.

You can watch the full interview with Sonal and know more about Eco Deco on the YouTube channel.

Add comment