Sometime back, when we asked one of the owners of a local grocery store, what is the biggest challenge they faced on day to day basis “Sir, my biggest pain is the fruits and vegetables which I have to throw after 3-4 days from the day of purchase. That is not only a monetary loss but it pains to throw the food”

This is not a specific problem for a specific owner, this is applicable to most of the businesses that sell fruits and vegetables. A few of them might sell it off at a cheaper rate or donate it to the unfortunate, but most likely the wasted food ends up in the landfills.

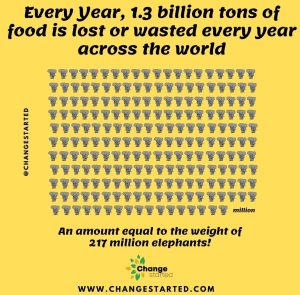

Food wastage is a monumental problem – Globally, 1.3 billion tons of food is lost or wasted every year—an amount equal to the weight of 217 million elephants!

Staggering, one-third of the food in the world gets wasted either they are not eaten, or they are wasted and not surprisingly fruits and vegetables have the highest wastage rates of any food.

India’s record in food wastage is probably even worse, as per an estimate by the Food and Agricultural Organisation (FAO) approximately 40 percent of the food produced in India is wasted every year.

As we can imagine, fruits and vegetables are highly perishable food items and due to fragmented food systems and inefficient supply chains, they are more likely to get spoiled or wasted.

What if there is a solution that can keep our fruits and vegetables last longer but without harmful chemicals.

GreenPod Labs is an organization that has developed a product that can solve the major problem of food wastage which is safe and cost-effective. Chennai-based biotechnology company, GreenPod Labs’ proprietary solution extends the shelf life of fruits and vegetables during storage and transport.

The agri-tech company’s active packaging solution activates in-built defense mechanisms in fruits and vegetables to preserve their quality. The solution comes in a small sachet that contains some powerful plant-based ingredients that also prevent the microbial growth of food items.

We got a chance to speak with the founder and CEO of the company, Deepak Rajmohan to discuss the solution, the secret ingredients of the GreenPod solution, and the future plans.

With a master’s in food science and a short stint in US-based food companies, Deepak decided to move back to India and solve the massive food wastage problem.

Here is an edited version/excerpts of our conversation with Deepak Rajmohan, on his journey, about GreenPod Labs, the reasons for starting this company, and future plans. For the full discussion please watch the video.

Tell us about your Journey?

I completed my graduation in Agricultural engineering from India and did my master’s in Food Science from the USA. Subsequently, I worked as a food scientist in the USA for three and a half years.

In the first half of 2019, I decided to quit my job, moved back to India, and started GreenPod Labs in the later part of 2019.

How did you identify the food wastage problem?

Back in the USA, I was working on a few projects which were about minimizing food waste in the food industry – like minimizing food wastes in the beer & wine industry which are the big generators of food wastes.

I started exploring various aspects of food wastage.

As a consumer when I buy a strawberry box, within a day or two it gets spoiled and that is a huge pain. Then I studied that India is the second-largest producer of fruits and vegetables, but 40% of the fruits and vegetables are lost before reaching consumers.

However, the food waste problem in India and the USA is completely different. In the USA 35 percent of the food waste happens after it reaches the consumers whereas in India 40 percent occurs before reaching the consumers.

I realized that infrastructure is not there in India to minimize this loss and that was the point where I decided that this was the problem worth solving. This motivated me to come back to India and work on a solution for food wastage.

In the US, there were few companies that were working on the same problem that gave further validation that the industry is also looking for a product.

How did you go about with the solution?

The initial product that I decided to develop for India was a solution for cold storage. I traveled across many parts of the country and interacted with various stakeholders of the food industry like farmers, distributors, e-commerce players, retailers.

I realized that high-cost solutions will not work for the Indian market. That’s when I thought of a new technology which is also growing in the USA. It is active packaging, in this either some compounds are released, or some compounds are absorbed to keep the food intact and is a cost-effective solution.

The science used in this technology is a Défense-based mechanism which is new and requires a lot of R&D. It took us 3-6 months to develop the first product and since then it is in process of changes and upgrades.

Can you explain the solution in simple terms?

Our product is a small sachet, it is similar to little silica sachets we find when you buy leather shoes or leather bags.

These sachet bags contains proprietary formulations that contain plant extracts and edible ingredients. When your drop these packets near the fruits and vegetables, it releases compounds that slow down the ripening rate of a fruit or a vegetable and inhibit microbial growth.

Fruit like a banana spoils because of over-ripening while fruit like strawberry or fig spoils because of microbial growth. Our product controls those two reasons for spoilage.

How does this work?

When the fruits and vegetables are stored in a crate after the harvesting, the packet is dropped in the crate. In this way, the quality of the fruits and vegetables is retained throughout the supply chain and its shelf life is increased.

If we introduce the product at a later stage, then control of ripening rate.

Can you tell us a little secret of what is inside the sachets?

The compounds are made from plant-based edible products like extracts from corn and potato. Many Indian spices from our age-old traditions are also being used. Similarly, we extract compounds from plants, leaves, etc. In total, about 10-15 ingredients are used for the product.

The formulations differ from product to product, as each crop has its own unique features like water content, rate of ripening, etc. Therefore based upon the specific analysis of each crop their respective compounds are created.

What is the proportion number of packets required to the number of fruits and vegetables?

The amount of crop which can be preserved by one packet differs for different crops – like for tomatoes it is 5-7 Kgs, while for figs it is 3-4 kgs. On average we can consider 1 packet for 5-7 kgs of fruits and vegetables

How do you target your stakeholders and customers?

Surprisingly, customers are very receptive to the problem we are solving. At present GreenPod Labs is working with 25-30 large customers and 90 percent of them are in-born requests. This shows that the companies are looking for solutions to this problem.

In the case of the farmers they are facing a number of problems:

- Incurring losses because of spoilage,

- Not paid as per the quality,

- Not able to reach new markets,

- Unable to take leverage in case of price fluctuations.

For high premium crops like mangos, strawberries, and figs, the problem is even more severe.

Conserving the fruits and keeping the quality intact, our product is able to address these problems, increase their income and enable them to reach new markets.

How do you compare your product to traditional & existing methods?

The current infrastructure we have, the cold storage capacity in our country can only hold 10-12 percent of the total production. Out of that 70-80 percent are for potatoes. Therefore the available space for most of the other crops is very little. Additionally, cold storage does not protect the crops from microbial growths and spoilage.

Another problem which we have found is that farmers are not willing to use cold storage due to high costs etc.

The product which we provide overcome the problems related to cold storage at very reasonable costs and also slows down the ripening rate.

What is the feedback that you have received for your product?

The product has performed well as it has the ability to extend the shelf life by 50-60% while retaining the texture, flavor, and overall experience. Moreover, we are able to minimize the microbial growth and weight loss of fruits and vegetables.

The feedback has been positive and every time we have received any recommendation we have made improvements and launched a newer version.

What is the size of the team?

Currently, the team is very small and comprises members from the R&D and Operations. The founding team is myself and Vijay Anand, where I lead the executive part and R&D, while Vijay takes care of operations.

What are the future plans?

We are super passionate to solve the food waste problem from a broader perspective. The product which we have developed will provide solutions to problems of hunger, food wastage with respect to climate change, and judicious use of natural resources.

Currently, we are working on the fruits and vegetables, over the period we will move to grains, seeds, dairy, and poultry. We will develop new products for each of these areas and also explore international markets once we establish ourselves in India.

In the age of open markets, many food items are imported and we have seen harmful chemicals being used on them, what is your take

Being a food scientist I do not buy any product that has too many chemicals in it. Hence, if I am developing a product I want to ensure that it is ethical, safe, and free from chemicals.

Our product is completely safe in terms of the use of ingredients which comprises mainly plant extracts and plant polymers.

What challenges did you encounter in your journey?

There have been various challenges in the development and R&D of the product as the science is in the initial stages of development. Then testing the product, talking to multiple stakeholders, and then scaling the product also brought its own set of challenges.

The idea behind the name GreenPod Labs

Pods are the outer shell of peas or beans. Our product helps in creating a shell that helps in increasing the shelf life of the food items.

Green signifies that we are environment and sustainability focussed and Labs because we are R&D focussed.

What is your personal connection with the environment and nature?

As I was associated with agriculture, I have always been conscious about my consumption patterns, food wastage, and my food choices.

The other thing which I associate with is plastic waste, wherever possible I minimize my use of single-use plastic.

You can watch the full interview with Deepak and know more about GreenPod Labs on the YouTube channel.

Do you know, that the average per capita food wastage globally is 121 kg?

United Nations Environment Programme along with WRAP released the Food Waste Index Report 2021 and glaringly about 17% of total food available to consumers in 2019 was thrown and wasted.

Here are some other solutions to food wastage.

While we are discussing food wastage, you can watch this small video on some simple ways to avoid food wastage at an individual’s capacity.

No information is available about the availability of the sachets , price etc .