If you happen to visit India’s national capital region (NCR) from September to November, you will be greeted with haze, smog, and air pollution.

While there are multiple factors contributing to Delhi’s pollution, one leading cause is the massive burning of paddy crop residues, especially in those months.

Stubble burning is a cheap and fast method to clear away crop residue that mechanized harvesting leaves behind. Hence, farmers regularly resort to burning their crop stubble, leading to severe air pollution in Delhi and its adjoining regions.

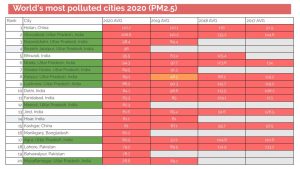

Not surprisingly, as per the data compiled by IQAir, 15 North Indian cities are in the top 20 lists of the World’s most polluted cities in 2020 (PM2.5).

The pollution caused by stubble burning poses a serious risk to people’s health and safety.

In spite of many solutions that have been tried, which include making burning crop stubble a crime as per Indian laws, implementation lacks strength. Farmers continue to burn residues every season, polluting the soil and air.

While crop stubble burning causing air pollution might be unique to north India and Delhi, but there is another pollution that strangles regions across the world, i.e the problem of plastic pollution.

Ever since plastic packaging became popular, the contamination of the environment by plastic waste has been a sad reality modern societies face.

Plastic comes in many shapes and sizes, including a variety that is commonly known as Thermocol.

Thermocol is a form of polystyrene (a kind of plastic called expanded polystyrene) and is widely used as a packaging material for electrical goods, furniture, and glass items, among others. Mainly because it is lightweight, has shock-absorbency properties, and provides a foamy cushion to protect delicate objects.

On the other hand, like other forms of plastic, Thermocol inevitably ends up in landfills, where it disintegrates into small pieces and eventually flows into our rivers and oceans.

Solution for air pollution (caused by crop stubble burning) and plastic pollution (thermocol)

One Indian company has taken it upon itself to solve the dual problem of plastic waste and agriculture waste. Started by Delhi-based entrepreneur Arpit Drupal, Dharaksha Ecosolutions is a sustainable packaging company that makes biodegradable materials from agricultural waste that can effectively replace Thermocol.

After spending many months in rural India, talking to farmers, evaluating the ecosystem, and researching possible solutions, Arpit went on to start Dharaksha Ecosolutions in 2020.

The biodegradable packaging solution by Dharaksha Ecosolutions is durable, strong, and cost-effective. We had an engaging conversation with Arpit, who shared wonderful insights on the reasons for crop stubble burning by farmers, his personal journey, and company plans for the future.

Below are the edited excerpts of our conversation, for the full discussion you can watch the video on YouTube.

Tell us about the journey that led you to start Dharaksha Ecosolutions.

I graduated in mechanical engineering in 2014.

One thought that has always stayed with me is that we belong to a fortunate set of people who have access to education and are able to afford it. Therefore I always wanted to give it back to society, not in form of philanthropy, but by utilizing my education and solving tangible problems.

During my engineering studies, I was part of a research group that worked on an agriculture machine. As this involved agriculture, I had the opportunity to visit various villages across India, and the thought of our privileged upbringing became even more deeply rooted.

In 2015, I went to IIT to do my master’s in the design of machine elements. At this time, Delhi was sometimes tagged as one of the world’s most polluted cities. Along with some of my friends, I decided to do something about it. That’s when I started my first company, Chakra Innovation. We created equipment that could capture pollutants from diesel engines and convert them into inks and paints. We were able to scale it up pretty decently.

Then, in 2019, another turning point came when the problem of crop stubble burning became so severe that the Supreme Court of India called Delhi like a gas chamber.

Having lived in Delhi since childhood, this was a shocking revelation. I felt that a technological intervention could sustainably solve this problem. I decided to take a break from my previous company and traveled to villages in Punjab and Haryana. I interacted with many villagers and farmers and even stayed with them to comprehend their rationale for stubble burning.

What I realized was that the villagers understand the ill effects of burning much more than people in the city. As they stay much closer to the fields, the smoke hits them first before it reaches cities. They also know that this is not just the smoke; the chemicals that they have put in the crops make the smoke highly toxic and hazardous. They also understand that it would destroy the organic content and friendly pests in the soil.

The reason that they choose to burn the crop waste is that they don’t have the time, which is because of a multi-dimensional problem. Back in 2010, the government of India came out with a regulation that you can only plant rice two weeks before monsoon because the water table was depleting. In order to save water, a regulation was introduced, which led to a delay in sowing the rice, resulting in postponing the harvest of rice.

However, the sowing of wheat cannot be postponed. Therefore, the time margin between the harvest of rice and the sowing of wheat got squeezed. Therefore, the farmers are left with no option other than to clear off their fields by putting them on fire. It still takes about 3 days to complete the process: On the first day, they have to sundry it; on the second day, they put it on fire; and on the third day, they have to wait for it to cool before they can do anything else. This was very important learning, and I was surprised that nobody was talking about the problem in such depth.

I researched the solutions that people in Western countries are utilizing to tackle this problem. Their solution was very simple, collect the waste, compress them into bales, stock them and utilize it later.

We could find a few pockets where these baling machines were used, where they were collecting the crop stubble waste, compressing it, and storing it. Whatever limited bales are created, they are utilized to provide them to furnaces, where, again, they are burnt. Since it has a lower calorific value and higher moisture, they don’t get a fair price.

The bottom line that we understood was that if we could provide a fair price, farmers would collect and stock crop stubble instead of burning it.

We got a very strong validation in the Peva district, located on the borders of Punjab and Haryana. There is absolutely zero crop stubble burning in Peva, as there is a paper mill located in that region. They are utilizing crop stubble waste to create craft paper, which is basically the raw material for cardboard.

We thought, how can we scale up this demand and create products with much more demand, which can consume the entirety of this waste?

As we know, there is a huge challenge of plastic pollution and if we can create packaging out of crop stubble waste that can eliminate plastic and thermocol from the market, it will be a great synergy.

How did you manage to create the biomass packaging material?

Once we decided to get into packaging, we found a few players in Europe and US who were trying to create packaging from other agricultural waste like hemp. However, hemp waste is a very nutritional source while paddy stock (rice) is devoid of all sorts of nutrition.

It took us about two years to crack the R&D process and create a packaging material that can replace the thermocol and plastic. Our packaging material is a combination of engineering and biotechnology.

Fortunately, we onboarded a very good team of scientists and researchers and also got support from India’s best regional center of biotechnology.

Tell us about your product.

Our material is significantly better than thermocol in many aspects – cushioning capabilities, looks, texture, and surface finish and it is completely biodegradable. There is no raisins, chemical, binders, or colors involved in the manufacturing of the material. You can easily dump it as part of your kitchen waste and it will decompose in 60 days.

At this stage, we feel we can disrupt the problem of plastic pollution and simultaneously solve the problem of crop stubble waste burning.

How does the conversion work?

It is almost a one-to-one conversion; there is absolutely no waste generated in the manufacturing process. The crop stubble waste that we receive is entirely converted into packaging.

For every tonne of crop stubble waste consumed, there will be 0.8 tonnes of packaging material that we make, which includes a few additives.

How are you managing the supply chain?

For the sourcing part, we are able to onboard a few aggregators. These people talk to farmers, collect the material, make bales, and stock it for year-round supply. Just for the R&D phase, we collected 150 tonnes of crop stubble waste from over 75 acres.

As of now, we don’t pay the farmers, that is part of our plans as we expand. We make the payment to aggregators, which ensures that the collection of agricultural waste is happening free of cost for farmers. Currently, in most cases, farmers pay aggregators almost Rs. 10,000 (~US$ 130) per acre, our model ensures that farmers save that money.

On the consumption side, the scale at which large companies operate is humongous. We visited one of the manufacturing facilities of an electric equipment company, where they had stacked a huge pile of thermocol. This stack, which was to be used for 2 days of packaging, measured 20 feet in height and continued for more than half a kilometer in length.

Once we got to see this level of scale, we realized that the packaging industry has the capacity to solve the entire crop stubble-burning problem.

What are your purchase costs, and are they cost-effective for your clients?

Aggregators collect the biomass from the farmers for free and then we pay the aggregators their operational costs. The landing costs we incur are between Rs 2,800 to Rs 3,000 per tonne.

As of now, our material is like 25 percent costlier than thermocol, but if you look at the value and impact it creates it is affordable and cost-effective. To put it in perspective, packaging for a television set would cost Rs 12, Dharaksha packaging would cost Rs 14.

This business would need big machines. Did you get the required investment?

It is a very capital-intensive business and it was difficult to raise the capital. Most of the investors like a software business compared to manufacturing intensive business.

Fortunately, we got backing from the investors at the right time, and now it is time to walk the talk.

Even biofuels can be made with crop stubble waste; what made you get into packaging?

In Biofuels, there are two categories: the first is to convert biomass into briquette, which can be used to burn in furnaces, and the second is to make biofuels.

The problem with biomass briquette is that paddy straw waste contains a very low calorific value and high silica content which makes it inefficient for burning. When we speak about biomass fuel, the calorific value has a huge role to play. Therefore biomass which has oil content makes better biofuel, like sunflower, soybean, etc.

The challenge with biofuels is the financial requirement and economic aspects, which were not viable for us. As a biofuel plant, it will take more than a decade to break even, and it will be difficult to recover the CAPEX.

That’s the reason we felt the Biofuels and biomass briquette are not very scaleable models; hence, we decided not to pursue other options. We were very clear to create an end-to-end sustainable business that does not leave any carbon footprint.

What is briquette?

A briquette is a compressed form of biomass. It is done by compressing the material under very high-pressure to create cylindrical pallets (similar to large capsules). Once the agricultural waste is converted into briquettes, it makes them easier to store.

What is your view on bio enzymes, which have emerged as a solution for the farmers?

Using Bio enzymes is a debatable concept as it takes 20 to 30 days to work, and farmers in Punjab and Haryana don’t have that much time. That’s the reason we see many farmers trying it for one season but do not use it in the next season. The attrition rate is very high; therefore, we have to wait for the next few seasons to see the impact.

Having said that, the problem is so big that we will be very happy if more solutions come forward.

What are the plans for the future?

The year 2022 will be very crucial for us to capture the market. In the next few years, we want to do a distributed manufacturing process model, which means that we will set up multiple manufacturing units that are closer to the client. This will help us source the material locally, produce it, and deliver it to the big corporations.

In the future, we also want to get into building furniture by increasing the strength of the materials. This would also help in preventing deforestation as we would be able to replace wood with our material.

In the next 5 years, we want to eliminate 25% of crop stubble burning, and in the subsequent 3 years, we want to eliminate 90% of crop stubble burning.

What is the idea behind the name?

I have a knack for picking Hindi and Sanskrit names. After a lot of thought, we came out with this name. Dharaksha defines the vision of the company in one word. We always want to be helping the planet and keep sustainability at the core of our products.

We call our company Dharaksha EcoSolution. Dharaksha has two Hindi words: Dhara means earth, and Raksha means saving. The idea is to save the earth from pollution.

What do nature and the environment mean to you?

One thing which I always believe is, to say what you believe in and do what you say. If there is a disconnect between these two, there is no meaning in doing anything in life, like if I talk about environmentalism but end up doing things that harm the environment.

For my personal commute, I am using electric vehicles for the last three years. I was among the first buyers of electric sports bike Revolt when it was launched.

In the last two years, at our home, we have not disposed of a single piece of plastic. Whatever plastic comes into our home, we store it and once it reaches a reasonable quantity we send it to a recycler. We are also working to have a bio-composter at home, such that all food waste that we generate can be converted into compost.

You can watch the full interview on our YouTube channel.

Add comment